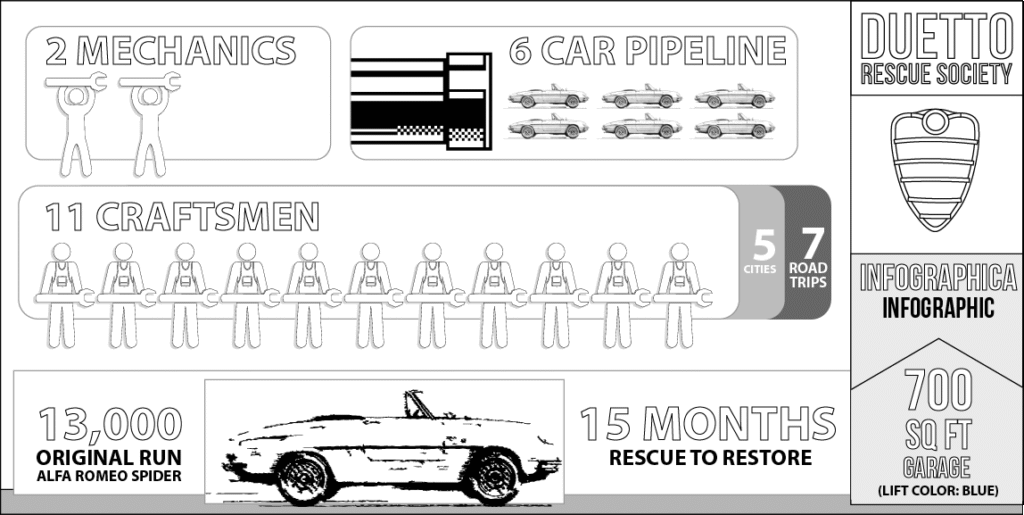

INFOGRAPHIC | OVERVIEW | DRS RESTORATION STORIES

We take pride in the journey from rescue to recovery so when you purchase a classic Alfa Romeo Duetto from DRS, we present you with a custom-bound history book demonstrating its recent restoration providence. We share some of those moments with you here to share our joy of taking on these projects and appreciating every step. In addition, once each project is viable, we name our restorations vehicles after Alfa Romeo female racing drivers.

RESTORATION JOURNEY

Our restoration process involves several phases following acquisition or “rescue”.

Following acquisition, the restoration car travels to Kensington, CA via flat bed. Once in Kensington, the car is hoisted onto our lift and stripped completely rendering just frame, two doors, trunk and hood and that’s it. The car is up in the air on a lift. Then the vehicle is lowered down onto custom made dolly and bolted onto the dolly. Now it’s just doors, hood, trunk all bungy corded.

From there we ship the car via flatbed trip to Sacramento, CA. In Sac: car is sand or bead blasting (bead of glass) which is more uniform material than actual sand, inside and out, door jams, everything to blow off existing paint and/or rust. Then car is sprayed with clear lacquer finish to prevent further rusting to arrest the rusting process.

They drive up to Sac and review the actual state of the body. Body inspectors! Put together list of all of the body work that needs to be done to the car which could be a sharpie circle around a dent to a fender so badly damaged that it needed to be replaced. List includes list of new body parts that we need to buy. Car still lives on Dolly. Might come off during bead blasting because the dolly connects on four points. Bead blasted, clear-lacquered, dropped to dolly, dropped to flatbed trailer.

Trip across town SAC to body shop. This where we remake the body as new. So from there she will sit for inspection by the body worker where we’re actually buying new parts and the new parts have to be trimmed to fit, welded in place. The welds have to be ground down. Dents have to be repaired. At which point we do a next to final inspection. When they think they’re done doing the body work they put a light grey primer that we go to SAC and we do an inspection and make final corrections. Minor dimples, scratches, things we missed using literally a sharpie pointing out what needs to be repaired. From that point, we by now we selected paint color. Paint is ordered. And the car is painted at the body shop. Now the car is painted. Now she is on the dolly, but off temporarily for painting. Back onto dolly, back onto flatbed, rides back to Kensington. In Kengsington (Berkeley) off dolly and up in the air. Onto the lift. Put on undercarriage, suspension, breaks, axels, and wheels. We run the electrical wire harness which is the “loom” big bundle long snake of wires that runs from the front of the car through the passenger compartment into the trunk and they fan out to their respective places, engine, back of dash, rear tail lights, etc. We put that in but don’t connect it to anything.

This is where Odette is right now. She did not come with a windshield so we had to install a new windshield and she is preparing to install the dashboard. Once the dash is in, Odette on flatbed off the dolly either to Las Angeles or Novato to one of two mechanics we work with where she shall receive engine and transmission and become and functional car. So these guys connect all the electrical and connect everything related to fuel and everything related to brakes to turn her into a functional car.

At this point she is missing her interior and her convertible top. Otherwise she’s put together. I think what’s going to happen is same shop, so no traveling, mechanic installs seats, trunk, convertible top which is two pieces: steel armature, and the canvas top is stretched over that and affixed to the car.

– From there, in a perfect world, she is delivered to her new home.

Restoration Stories

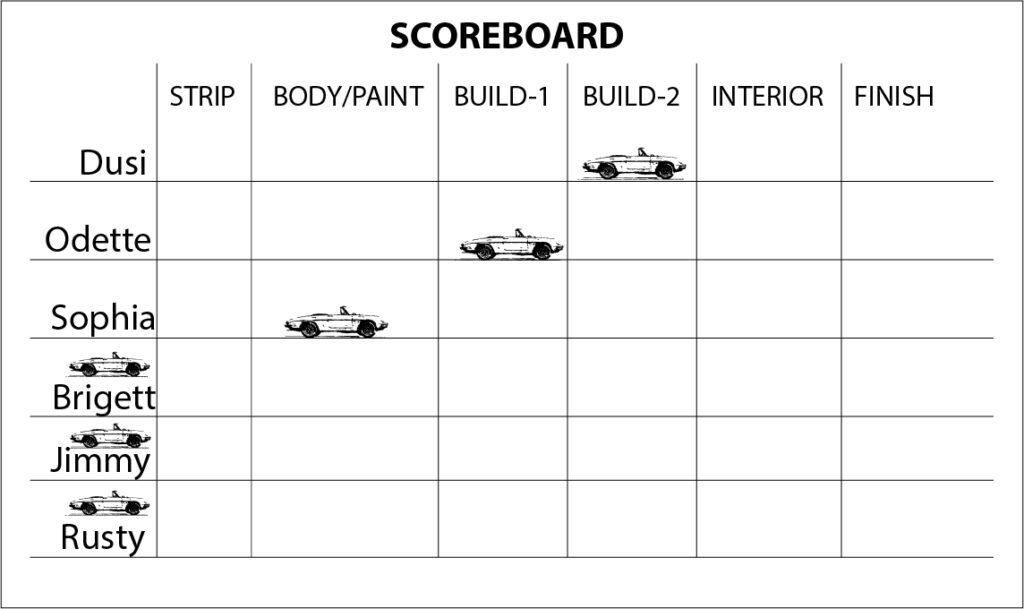

Our restoration process involves six phases following acquisition. Each of our restorations is a unique challenge but broadly organized around a process of necessity. Each restoration is in a different part of the restoration process which is elaborated below. Each restoration also has it’s own dedicated page.

DUSI

1966 “DuSI”: Purchased in 2022, paint, suspension complete, engine build started

ODETTE

1966 codnamed: Cecilia, now referred to as “Odette” Purchased in 2024 and currently undergoing body restoration

SOPHIA

1967 Sophia, (stalled project) from son after father passed, partially disassembled

BRIGETT

1968 Brigette A real euro 1750 – running, but not great, rust issues, etc

JIMMY

1969 Jimmy Barely road worthy, stalled restoration referred to by our mechanic

RUSTY

1969 Rusty Non running, very rusty fully assembled, awaiting start of rescue